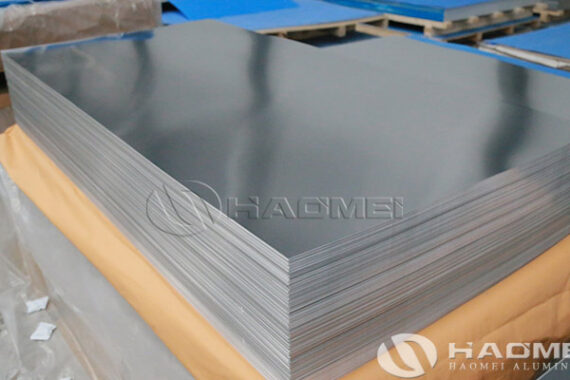

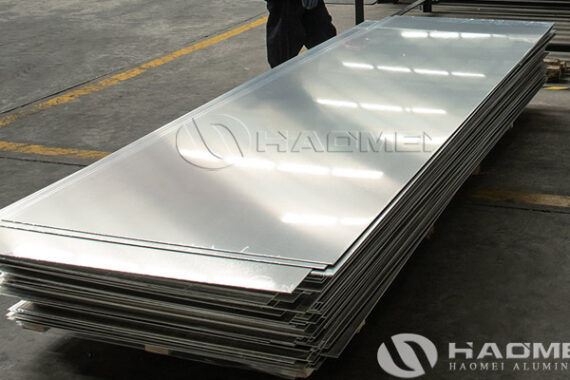

ASTM 5083

ASTM 5083 aluminum plate is an aluminum alloy material with excellent performance, the main components are aluminum, magnesium and manganese. 5083 aluminum has high strength, corrosion resistance and weldability and is widely used in ships, automobiles, aerospace and other fields. The specifications of ASTM 5083 aluminum sheet are usually based on its thickness, length and width. Different…