Aluminium Alloy For Car Body

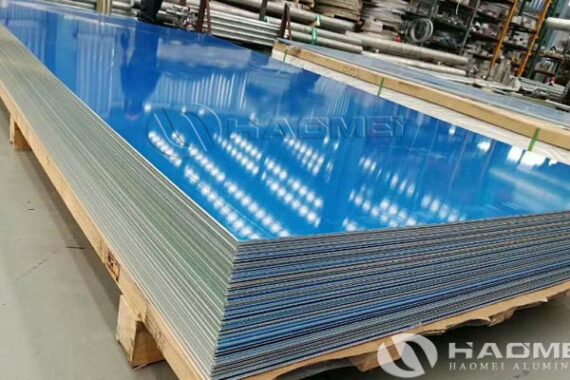

Aluminium alloy for car body panels in automotive manufacturing include 5000 series 5, 6000 series and 7000series. These aluminum plates are usually in temper such as O, H111, and H22, and have good machinability, strength, and corrosion resistance. The following are the common characteristics and applicable temper of aluminium alloy for car body: 5000 series aluminium alloy plates: Mainly…