Aluminum 7075 Mechanical Properties

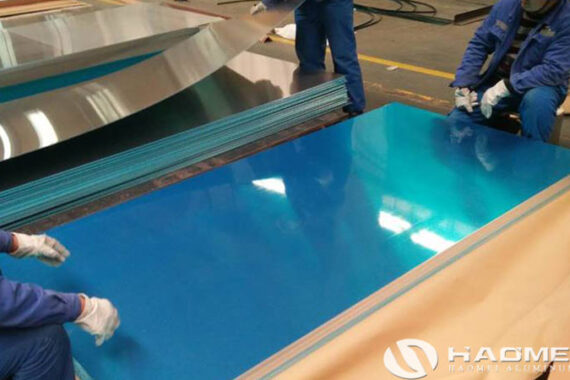

7075 aluminum plate is an Al-Zn-Mg-Cu series alloy, which can be heat treated and strengthened, where Zn and Mg mainly play the role of strengthening, and the role of Cu is mainly to improve the corrosion resistance of the alloy. 7075 aluminum plate is a super hard aluminum alloy, aluminum 7075 mechanical properties are very good, tensile…