Alloy 6063 is an aluminum alloy with magnesium and silicon as alloying elements. The standards governing its composition are maintained by the Aluminum Association. It has generally good mechanical properties and is heat treatable and weldable. 6063 alloy is the most common alloy used for aluminum extrusion. It allows complex shapes to be formed, has a very smooth surface, is suitable for anodizing and is therefore ideal for architectural applications such as window frames, door frames, roof and industrial profiles, framing aluminum profiles. Applications requiring higher strength typically use 6061 or 6082 aluminum alloy.

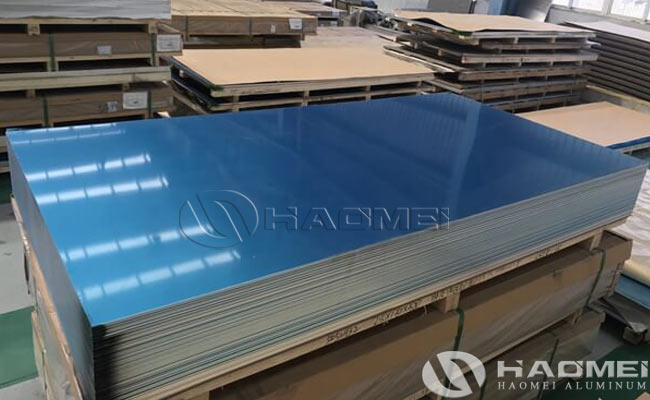

The alloy 6063 national standard aluminum plate belongs to the 6000 series aluminum-magnesium alloy. The 6063 aluminum alloy has high strength and has good machinability, corrosion resistance and welding performance after hot rolling treatment. However, due to its complex processing technology and high technical requirements, the price of 6063 aluminum sheet is relatively high.

Chemical composition of 6063 aluminum alloy:

Aluminum Al: Balance Silicon Si: 0.20~0.60 Copper Cu: 0.10 Magnesium Mg: 0.45~0.9 Zinc Zn: 0.10 Manganese Mn: 0.10 Titanium Ti: 0.10 Chromium Cr: 0.10 Iron Fe: 0.35 Individual: 0.05 Total: 0.15

The mechanical properties of aluminum alloy 6063 are:

The hardness of 6063 aluminum is between 8-12HW, the tensile strength is ≥205mpa, the elongation stress is ≥170mpa, and the elongation is ≥7%. This is fairly average among 6-series aluminum alloys.

Alloy 6063 aluminum has excellent corrosion resistance, and its anti-oxidation ability can be greatly exerted after surface treatment. It can be used in harsh outdoor environments for more than 25 years. The plasticity of 6063 aluminum is also relatively strong, and the extrusion formability is good, so the 6063 grade is the main grade of extrusion profiles. Almost all architectural profiles and industrial aluminum profiles use 6063 aluminum.