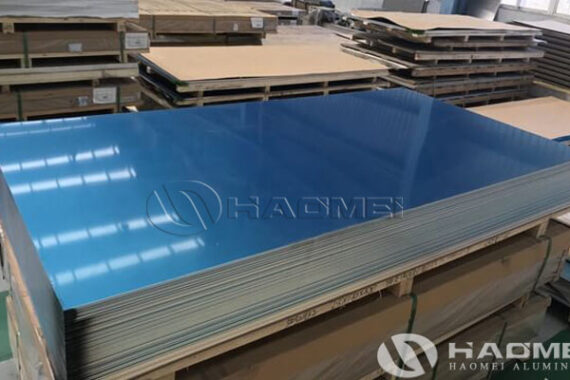

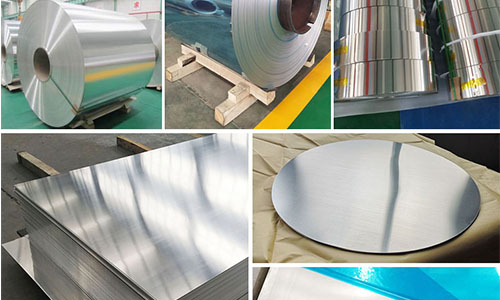

1050 H16 Aluminum Sheet Manufacturer

1050 aluminum sheet belongs to the 1000 series pure aluminum sheet. The 1000 series aluminum sheets are named based on the last two Arabic digits, which determine the minimum aluminum content of the series. The last two digits of 1050 aluminum are 50, and according to the international alloy designation system, the aluminum content must be above…