Aluminium alloy 1050 has features of low density, good conductivity, good corrosion resistance and excellent forming property. It’s a representative of industrial aluminium alloys which contains the highest share of aluminium element of all alloys. Take 1050 for example. It has 99.% aluminium and only 0.5% other metals. The slight share of other metals affects little the overall mechanical and chemical properties of the alloy. The hardest of industrial alloys, 1100, still has 99% aluminum, with only 1% of other metals. Therefore, the features of 1000 series of alloys are more or less the same. The specific differences lie in numbers of each property.

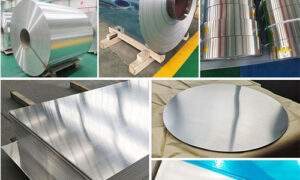

1050 aluminium alloy displays all common features of industrial aluminum alloys: low density, good electrical and thermal conductivity, good corrosion resistance, good plastic processing performance etc. The alloy can be processed into plates, strips, foils and extruded products, etc., and can be used for gas welding, argon arc welding, and spot welding. 1050 aluminium alloy cannot be strengthened by heat treatment, and its strength can be improved by cold deformation. The only form of heat treatment is annealing. The starting temperature of recrystallization is related to the impurity content and the degree of deformation, generally around 200°C. 1050 aluminum alloy is often made into sheets, coils, strips and foils. It finds applications in a vast of fields, too, such daily necessities, cookware, lamps, reflectors, chemical industry containers, heat sinks, signs, electronics, licence plates, nameplates, electrical products and so on. All these requirements have one thing in common: they require low in hardness but relatively high in corrosion resistance and forming ability.

The price of 1050 aluminum alloy is lower than many other aluminium alloys, for its manufacturing process is quite mature and large-scale production of the alloy is very easy. Thus if you can choose 1050, do not use 1100, the price of which would be higher.