Aluminium alloy 1100 datasheet is a pure aluminum series with relatively low strength and excellent ductility, capacity, welding and corrosion resistance. Anodizing can further improve corrosion resistance and obtain a beautiful surface. But the intensity is low. Other process performances are basically the same as 1050A.

The pure aluminum plate series is based on the last two Arabic characters to determine the minimum aluminum content of the series. For example, the last two digits of the 1100 series are 00. According to the international brand naming principles, the aluminum content must reach 99.00% as a qualified product. my country’s aluminum alloy technical standard (GB/T3880-2006) also clearly stipulates that the aluminum content of 1100 reaches 99.0%. Its strength is relatively low, and it has excellent ductility, formability, weldability and corrosion resistance; after anodizing, the corrosion resistance can be further improved, and a beautiful surface can be obtained at the same time; but it cannot be strengthened by heat treatment.

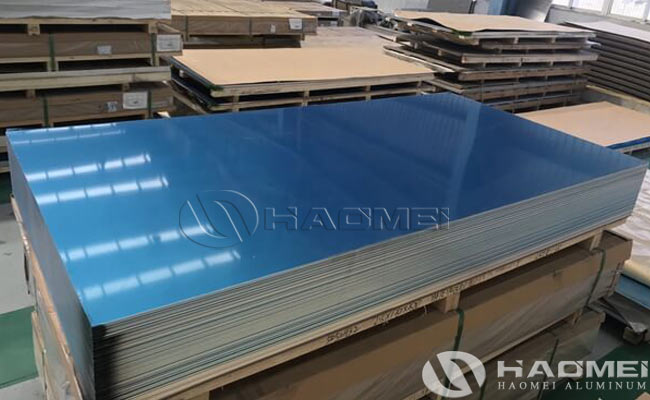

1100 aluminum sheet is usually used in utensils, radiators, bottle caps, printed boards, building materials and heat exchangers, and can also be used as deep stamping products. It is used in everything from cookware to industrial equipment.

Aluminium alloy 1100 datasheet chemical composition:

Aluminum AL: 99.00

SI: ≤0.45

Copper: ≤0.05~0.20

Magnesium mg:

Zinc Zn: ≤0.01

Manganese MN: ≤0.035

Titanium Ti:

0 V: ≤0.05

Iron Fe: ≤0.35

Note: Single: ≤0.05

Aluminium alloy 1100 datasheet mechanical properties:

Tensile strength σb (MPA): ≤137

ELM expansion δ10 (%): ≤3