Which is better, 6061 or 7075 aluminum? Each aluminum alloy has its advantages and disadvantages. 7075 aluminum is stronger and more rigid, while 6061 aluminum is less strong and more ductile. Typically, 7075 aluminum alloy is used in commercial applications such as automotive parts and molds. Compared to the 6061 aluminum, the 7075 aluminum is less expensive and suitable for commercial applications, while 6061 aluminum alloy is much more expensive.

6061 aluminum alloy has good weldability and formability, and is easy to weld. It also has a high level of corrosion resistance. However, if you plan to use it outdoors, you may want to consider 7075 aluminum alloy as it has a higher zinc content. However, it is important to note that both 7075 aluminum and 6061 aluminum alloys are suitable for indoor and outdoor use.

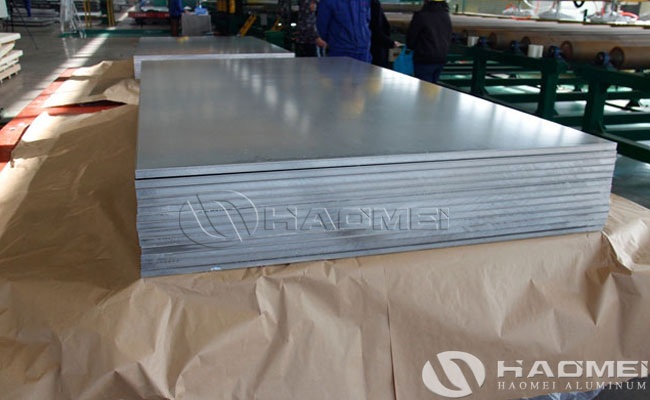

Aluminum plates are also available in 7075 and 6061 aluminum alloys. These aluminum alloys are made from different types of metals, but they share some similar qualities. In general, 7075 aluminum plate contains more zinc than 6061 aluminum plate. It’s also stronger than the 6061 aluminum sheet, but lighter. So for some apps it’s a better choice than others. The difference between the 6061 and the 7075 aluminum is minimal.

Another factor driving the decision 6061 and 7075 aluminum which is better is about their strength. While 7075 aluminum alloy is slightly stronger, 6061 aluminum alloy is softer and bends easily and will not return to its original state. The difference between the 6061 and 7075 alloys comes down to a matter of preference. Certain types of aluminum are better for bending, while others can be machined. A popular example of an alloy used for machining is 6061-T6 aluminum alloy.