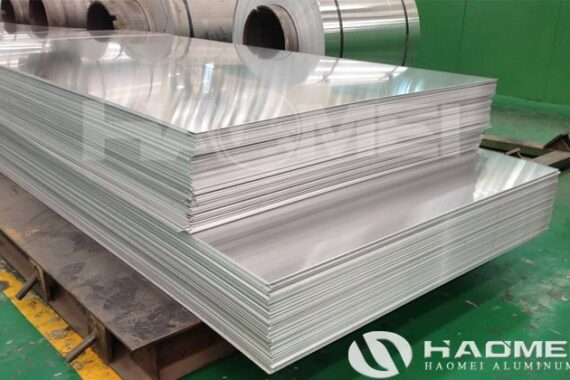

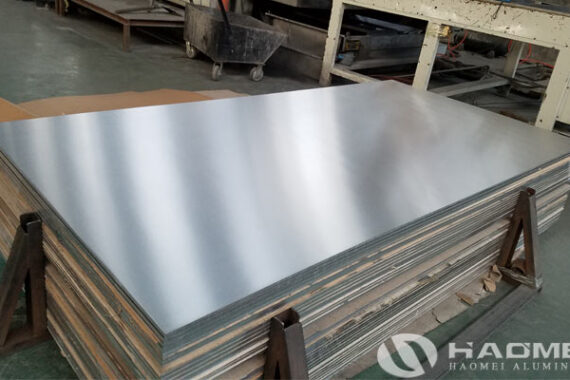

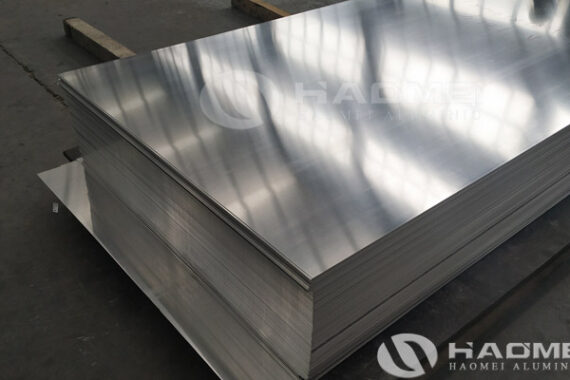

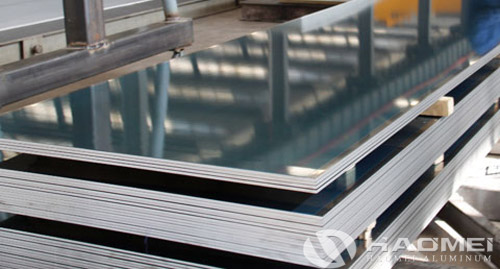

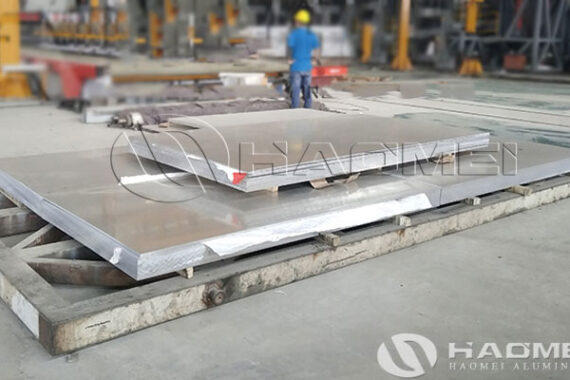

Marine Aluminium Grades

The selection of marine aluminium grades alloy materials is relatively strict, at present, aluminum alloy products such as 5083 aluminium plate, 5086 aluminium plate, 5454 aluminium plate, 5754 aluminium plate and 6061 aluminium plate are mostly used. In practical applications, the advantages of marine aluminium alloys are very obvious. First, the specific gravity is small, which can reduce the…