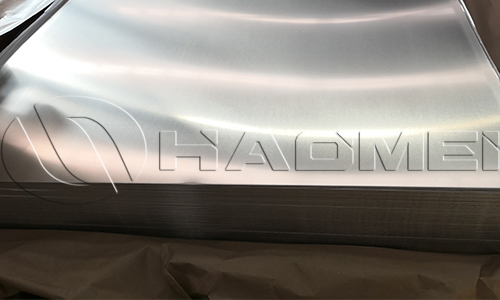

5083 h111 aluminium alloy sheet for tankers

The ordinary tanker body aluminium sheet proves to be 5083 h111 aluminium alloy sheet. 5083 aluminum alloy has the characteristics of low density, high strength, and strong corrosion resistance, and plays an important role in the lightweight building of tank trucks. In fact, its role does not stop there. Lighter aluminium body of a tanker…