Why Is Aluminium Used In Spacecraft

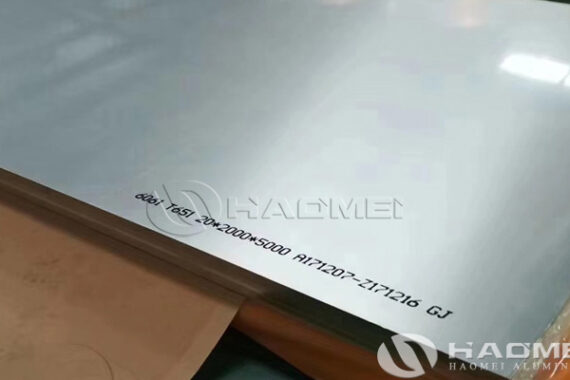

In aviation equipment, different parts have precise selection requirements for the selection of aluminum alloy materials. The aluminum alloys used in different parts of the aircraft mainly include 2X24, 7X75, 7X5X, etc. With the continuous improvement of the aluminum alloy material process, the application grades in different parts of the aircraft are also constantly adjusted.…